Automation Projects Showcase

Video Gallery

Up & Down Ball Roller Mat for Heavy Material Movement

A 150KG object is effortlessly moved by a single operator with minimal effort.

This Up & Down Ball Roller Mat is designed for smooth material transfer between different height levels. Installed on a height-adjustable table, the loading side is elevated, while the unloading side is lowered for seamless operation.

Designed and implemented by ELTRIVE Automations, India.

High-Precision ACB Testing System with LabVIEW Integration

To overcome the limitations of manual testing, which is time-consuming, less accurate, and not suitable for repeated cycles. Our setup features two frames supporting both 3 and 4-pole ACBs, compatible with AC and DC sources. Parameters like frame type, pole count, and source are configured via LabVIEW. A motor positions the ACB in the test area, and once confirmed by sensors, the unit is securely clamped on all axes. A stepper motor with load cell performs repeated closing and tripping actions. Load cells measure the force required, and feedback signals are monitored in both load and no-load conditions. LabVIEW captures and analyzes the data, automatically determining pass or fail status. This system allows high-accuracy, high-repeatability testing for any number of cycles with minimal human effort.

Automated Socket Transfer & Orientation System

Designed by Eltrive Automations

Boosts packing speed, reduces manual effort, and ensures precise socket handling between mismatched conveyor lines.

This system acts as a smart mediator between the production and packing lines. It handles sockets in batches of four, creating precise gaps and adjusting orientation to match packing requirements. Using pneumatics and vacuum pickers, it lifts and transfers sockets from the production conveyor to four separate packing tracks—even when heights and orientations differ. Controlled via HMI, the system streamlines the entire flow, ensuring fast, accurate, and efficient packing operations.

Switch Load Testing & Auto Sorting System By Eltrive Automations

At Eltrive Automations, we’ve developed a smart and streamlined system to ensure every switch from the production line meets top-quality standards. Each switch undergoes precise load testing to measure the force required to turn it ON and OFF. This data is instantly sent to LabVIEW, where advanced algorithms verify if the readings fall within the approved range. Based on the evaluation, switches are automatically directed to either the OK or Not OK bins—no manual sorting needed. The OK switches move straight to the packing line, ensuring zero delays and maximum efficiency. This fully automated process guarantees accuracy, speed, and reliability at every step.

Eltrive Automations presents a smart Transfer & Placement System built for seamless post-inspection handling.

Failed components are instantly diverted, while passed parts transition smoothly between conveyors moving in different directions.

With precise control via PLCs, HMIs, and stepper motors, the system ensures perfect synchronization.

Each component is accurately placed into the correct gap on the packing line.

The result? High-speed, high-accuracy automation that boosts your production flow.

Efficient, intelligent, and built for the future of manufacturing.

Speed Fuse Inspection & Barcode Traceability System

Designed and developed by Eltrive Automations, the Automated Fuse Vision Inspection System replaces slow and error-prone manual inspection with a fast, accurate, and intelligent solution. Each tray, holding 10 fuse components, is scanned for its serial number before entering the inspection area, where high-resolution cameras verify ampere ratings, markings, and bus bar alignment based on taught references. Unlike manual checks, this system ensures high-speed, consistent, and fatigue-free inspection with real-time defect detection. It highlights faulty components, generates barcodes for traceability, and significantly boosts efficiency, accuracy, and throughput—making it a smarter choice for modern fuse quality control.

Automatic Lable Pasting Machine

Eltrive Automations presents an advanced Label Pasting Machine designed for precise and efficient labeling of bottles, jars, and containers. The system ensures accurate label placement with the help of servo control, smart sensors, and an easy-to-use HMI interface, making it ideal for various industrial applications.

Built for reliability and consistency, the machine delivers high-speed labeling with minimal manual intervention. Its modular and compact design allows easy setup, quick changeovers, and low maintenance, ensuring a professional finish and enhanced productivity on every production line.

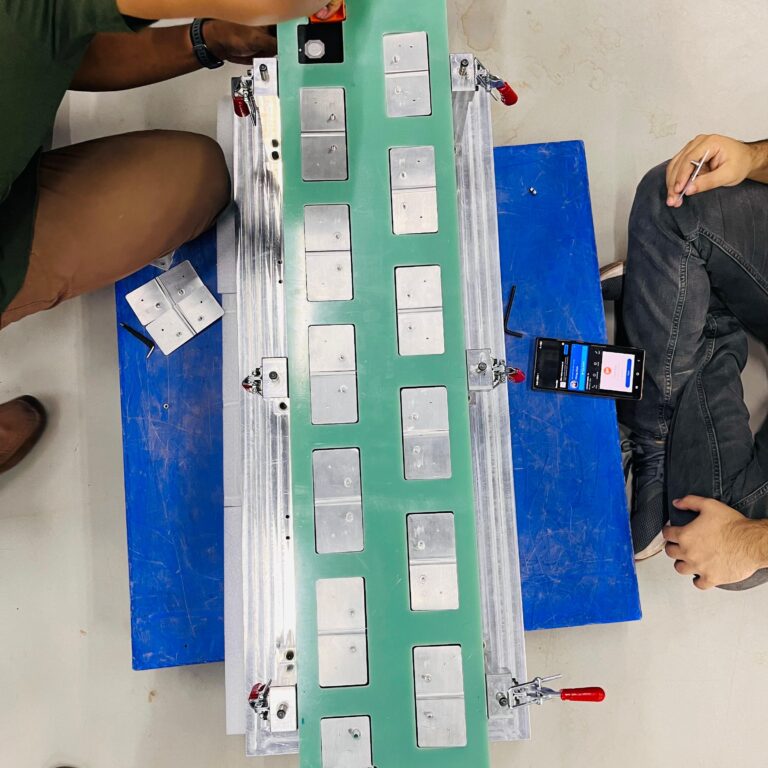

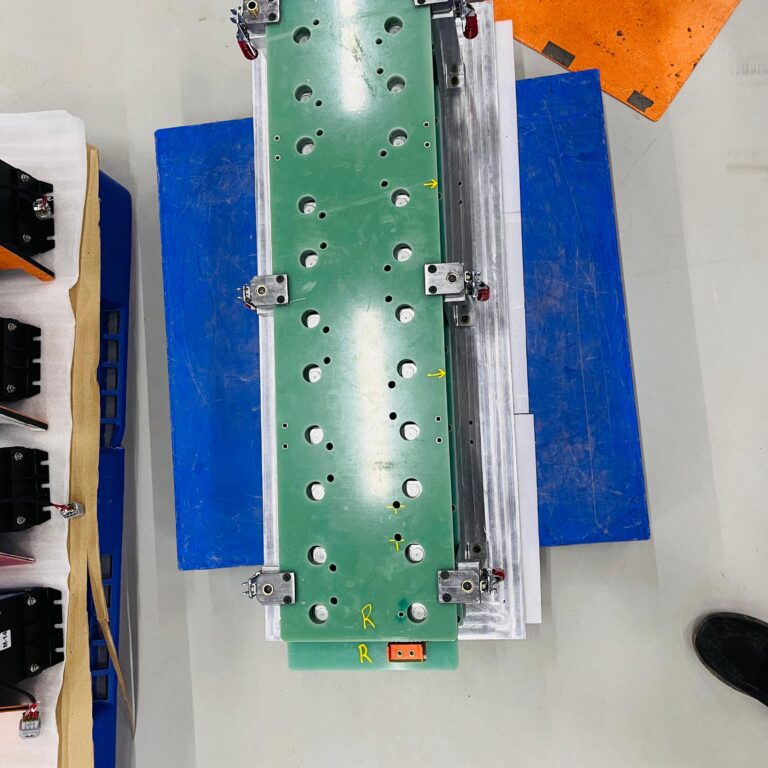

Smart Fixture Solutions for Advanced Battery Manufacturing

Our battery module fixture is engineered to deliver precision and reliability in the welding of busbars to battery packs. Designed with a modular approach, the fixture ensures accurate positioning, secure holding, and repeatable alignment throughout the welding process. Key elements such as busbar holders, alignment plates, guide blocks, toggle clamps, and support structures are integrated to achieve maximum stability while minimizing setup time. With carefully defined tolerances, the fixture provides both secure clamping and smooth handling of components, ensuring high-quality welds with consistency across multiple modules. The robust base and support columns reduce vibrations during welding, while durable materials like brass bushes enhance long-term performance and reliability. By combining accuracy, efficiency, and durability, this fixture supports faster cycle times, improved weld quality, and reduced manual errors, ultimately enhancing the safety and reliability of advanced battery systems.

Get Started

Contact us to discuss your automation project ideas. Share your vision and let’s create together.